Thermal conductivity silica gel sheet (1~ 15W)

Product features

application:

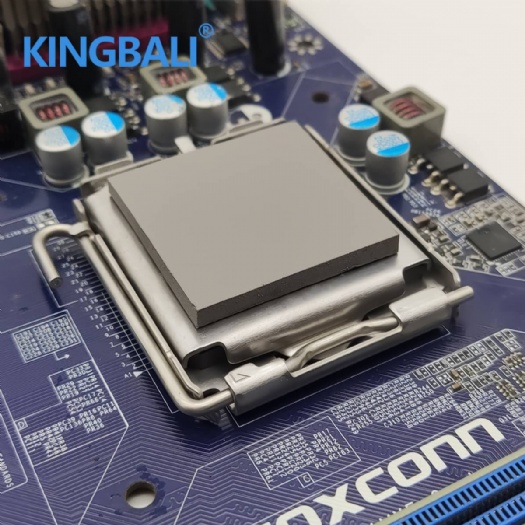

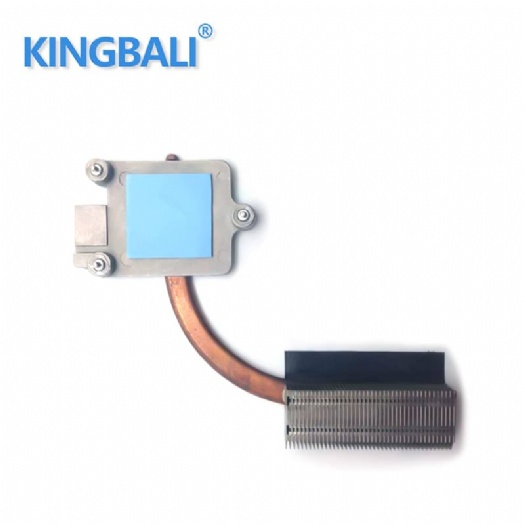

KINGBALI 9000 series thermal conductivity silica gel sheet widely used in LED industry, automotive electronics industry, new energy, PDP/LED flat panel TV, communication industry, home appliance industry.

Features and advantages:

KINGBALI 9000 series thermal conductive silicone is specially designed for use of gap heat transfer scheme, can fill the gap, to complete the heat transfer between the heating parts and cooling parts, also play a role such as insulation, shock absorption, seal, can meet the design requirements of the device miniaturization, manufacturability and practicability, applicability is wide and thickness, is an excellent thermal conductive filler material.

▪ Soft, good compressibility;

▪ 1 ~ 15.6 W/M.K thermal conductivity;

▪ Low thermal resistance;

▪ Fire rating reaches UL-94 V0.

EIGENVALUE

| Product number | colour | Thermal conductivity | Flammability rating | Dielectric constant (1MHz) | proportion | Breakdown voltage | Operating temperature | Volume resistance | Tensile Strength | hardness | thickness |

| 9200 | Off-white | 1.0W / MK | UL-94 V0 | 8.79 | 2.3g / cm 3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.45 MPa | 10~70 Shore 00 | 0.3~10 mm |

| 9300 | black | 1.5W/MK | UL-94 V0 | 6.54 | 2.7g / cm 3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.41 MPa | 10~70 Shore 00 | 0.3~10 mm |

| 9400 | maroon gray | 2.0 W / MK | UL-94 V0 | 7.22 | 2.7g / cm 3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.35 MPa | 10~70 Shore 00 | 0.3~10 mm |

| 9500 | yellow | 2.5W/MK | UL-94 V0 | 6.34 | 2.85g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.29MPa | 10~70 Shore 00 | 0.3~10 mm |

| 9600 | blue | 3.0 W / MK | UL-94 V0 | 6.33 | 2.89g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.23 MPa | 10~70 Shore 00 | 0.3~10 mm |

| 9700 | Fuchsia | 3.5W/MK | UL-94 V0 | 6.51 | 3.04g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.21 MPa | 30~70 Shore 00 | 0.5 ~10 mm |

| 9800 | white gray | 4.0 W / MK | UL-94 V0 | 6.5 | 3.09g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.15 MPa | 30~70 Shore 00 | 0.5 ~10 mm |

| 9900 | white Red copper | 5.0 W / MK | UL-94 V0 | 6.7 | 3.21g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.15 MPa | 50~70 Shore 00 | 0.5 ~5 mm |

| 9901 | white | 6.0 W / MK | UL-94 V0 | 6.1 | 3.11g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.14MPa | 50~70 Shore 00 | 0.5 ~5 mm |

| 9902 | white | 7.0 W / MK | UL-94 V0 | 6.13 | 3.13g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.14 MPa | 50~70 Shore 00 | 0.5 ~5 mm |

| 9903 | Dark gray | 9.0 W / MK | UL-94 V0 | 6.13 | 3.10g/cm3 | ≥4 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.11 MPa | 60 Shore 00 | 0.5 ~5 mm |

| 9904 | gray | 10.0 W / MK | UL-94 V0 | 6.13 | 3.15g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.08 MPa | 50~70 Shore 00 | 0.5 ~5 mm |

| 9905 | gray | 8.0 W / MK | UL-94 V0 | 6.13 | 3.43g/cm3 | ≥4 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.11 MPa | 45 Shore 00 | 0.5 ~5 mm |

| 9906 | gray | 11.0 W / MK | UL-94 V0 | 6.13 | 3.13g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.14 MPa | 50~70 Shore 00 | 1~5 mm |

| 9907 | Dark gray | 13.0 W / MK | UL-94 V0 | 6.13 | 3.13g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.11 MPa | 50~70 Shore 00 | 1~5 mm |

| 9908 | Dark gray | 15.6 W / MK | UL-94 V0 | 6.11 | 3.15g/cm3 | ≥10 KV (1mmDC) | -40~200 ℃ | 1012 Ω·CM | 0.11 MPa | 50~70 Shore 00 | 1~5 mm |

| standard test | Visually | ASTM D5470 | UL-94 | ASTM D150 | ASTM-D792 | ASTM-D149 | EM344 | ASTM-D257 | ASTM D412-1998A | ASTM-D2240 | ASTM-D374 |

| Note: The data recorded on this website are representative values rather than guaranteed values. To improve product performance, specifications are subject to change without notice. The use of the product recorded in this website is just an example. The product can have a variety of different application scenarios and environments, which are beyond our control. Therefore, whether the product is suitable for your production process and conditions, you need to make full use of it before using it. Evaluate to confirm whether its performance and effect are in line with expectations. For applications that need to be considered safe, please test and confirm their safety in advance. In addition, the company does not guarantee that the purposes recorded on this website will not infringe any patents. Before using this product, please carefully read the explanatory text and safety data sheet (MSDS) marked on the main body of the product. This product is manufactured for general industrial applications. Do not use for medical purposes. Since this product is a silicone product, low-molecular-weight siloxane may volatilize according to the conditions of use. Before use, fully evaluate whether the product performance is suitable for your needs and evaluate its safety. | |||||||||||